WELCOME TO AL GHAITH INDUSTRIES

OUR VISION & MISSION

We are committed to excellence in our endeavours and strive to maintain the trust and confidence of our customers. Conformance to business ethics and integrity enhances our reputation and enable us to attract and retain customers and employees alike

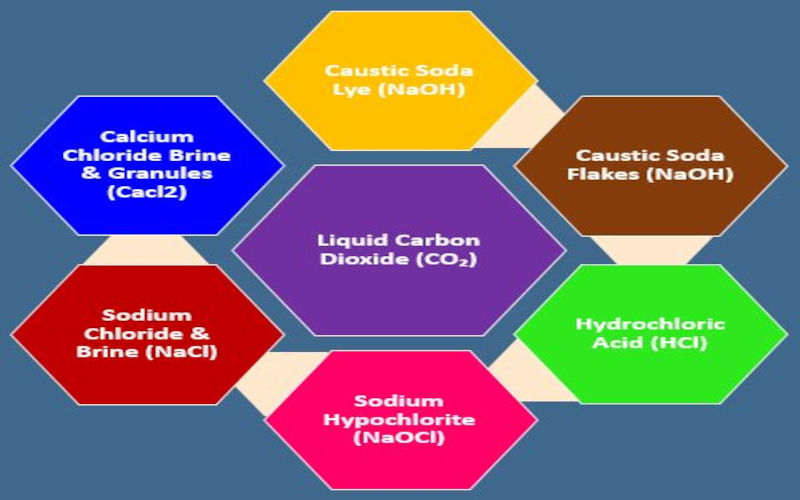

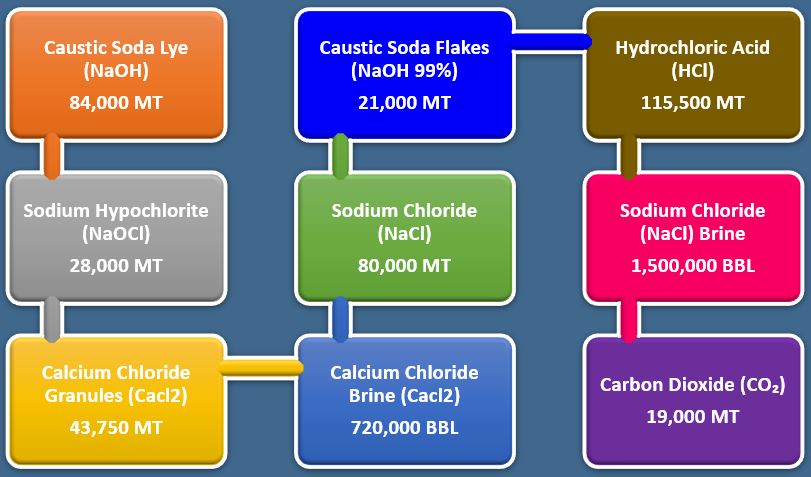

Al Ghaith Industries Chlor Alkali Plant is the biggest in the UAE and one of the biggest in the MENA region. Our Chlor – Alkali Products manufactured with State of the art membrane technology from Asahi Kasei Japan, which is the best available technology that is Environmental friendly and Energy efficient. production of Caustic Soda Lye 50%, Hydrochloric Acid 32%, Sodium Hypochlorite 15% and Calcium Chloride 97% was a success and within a span of less than two years we have a customer base of reputed Government, private industries and traders. With the plant expansion work was successfully completed simultaneously two new manufacture unit of Caustic Soda Flakes 99% and Carbon Dioxide 50TPD

We are catering to all the Oilfield Companies in the UAE and Oman with our Hydrochloric acid. Our Caustic Soda Lye and Sod Hypochlorite are consumed by the Power and Drinking Water treatment plants and also the sewage treatment plant. We also supply to various other end user including to Abu Dhabi Gas Company, Dubai Municipality, Dubai Water and electricity etc. We have a very modern Fleet of Bulk Road Tankers to deliver our products in UAE and Oman We are also looking forward to the international Market to have our presence in all the continents. We have team professionals in all the department who are always working towards maintaining our best quality, service and development, finding new ways to make our organization one of the best in the region.

INDUSTRIES WE SERVE

OMAN CAUSTIC SODA PLANT

Our upcoming Caustic Soda plant project in Oman is nearing completion

LATEST NEWS

- Hello world!Welcome to WordPress. This is your first post. Edit or delete it, then start writing!